Wednesday, 15 February 2023

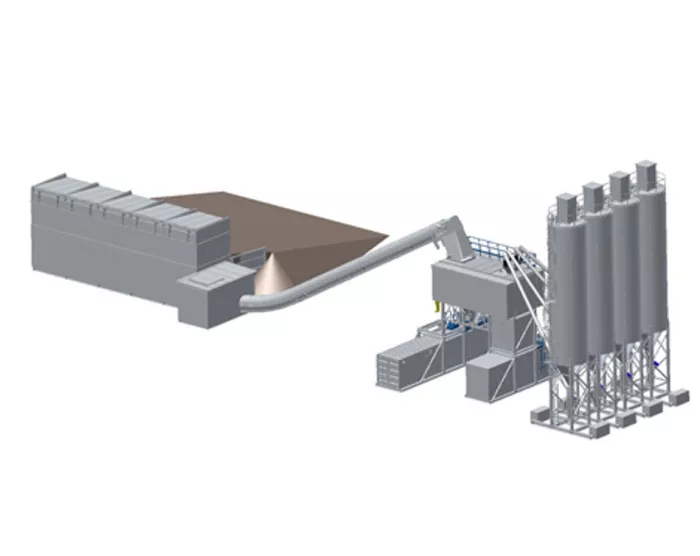

Flexible and fast transfer of the Kamet®Express concrete mixing plant to Erla Betong

When Erla Betong was building its first concrete mixing plant, the choice of the plant focused on Steel-Kamet's movable Express model. It was only two months after commissioning when the plant had to be moved. Erla Betong is very pleased with Steel-Kamet's flexible service, high quality equipment and record fast transfer.

Erla Betong, located in Gävle, ordered Steel-Kamet's movable Kamet® Express 100 concrete mixing plant as a turnkey package at the end of May. The plant was ready for use only three months after the order.

— We are very satisfied with the whole process - both delivery, installation and commissioning exceeded our expectations. I was positively surprised by how carefully and thoroughly everything was planned. Steel-Kamet had considered everything down to the details; even the plant's surrounding lighting was considered, says Erla Betong's Plant Manager Leif Carlsson.

Shortly after commissioning, it became apparent that the permit to operate for the Erla Betong site was not adequate. Despite the movability of the concrete mixing plant, a building permit would have been required for the site, which was not possible in this case. Instead, Erla Betong found a new site four kilometres away from the original place and re-contacted Steel-Kamet.

— The transfer went smoothly and very quickly. The disassembly took place on Tuesday and already on Thursday the plant was moved, installed and ready for production. Everything worked as it should, and we didn't have to make any changes ourselves, continues Carlsson.

Steel-Kamet's Project Manager Jarkko Manninen confirms that the main and most important advantage of the Express model, in addition to reliability and year-round availability, is its flexible and cost-effective movability.

— Our Express plants are manufactured and installed on a plug-and-play basis. This means, among other things, that potential transfers do not require electrical or automation expertise, which saves time and keeps costs under control.

Eric Larsson, CEO of Erla Betong, is also pleased with the delivery and relocation of the plant.

— Steel-Kamet has a functional overall concept where everything works, including the price level. The Express model's standard of equipment was suitable for our operation, and it is also well suited to the Nordic climate, sums up Larsson.

Technical features

Product: Kamet® Express 100

Capacity: 100 m3/h

Kamet® services: design, delivery, commissioning, transfer