Wednesday, 04 October 2023

Complete success of the project

Steel-Kamet received a request from its long-term partner Betset for the replacement of a vertical-shaft mixer and the renewal of two skip hoists at the company's plant in Nurmijärvi. Betset's Production Director states that the project could not have gone better in terms of quality and schedule.

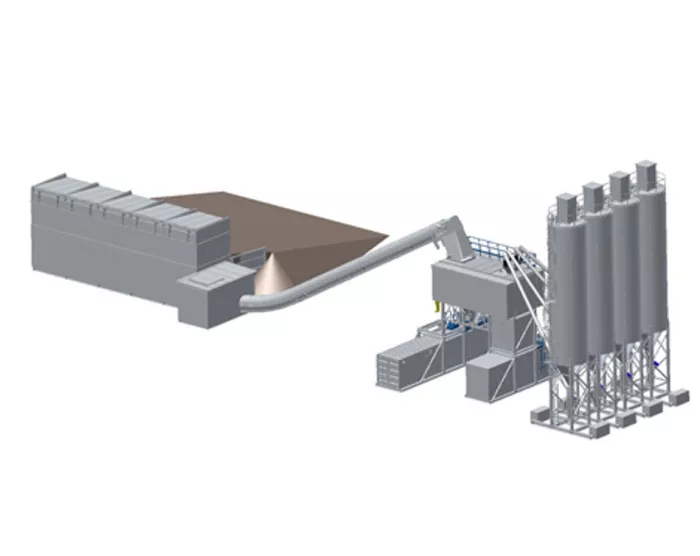

Betset's Nurmijärvi plant is manufacturing hollow-core concrete slabs and wall elements, among other things. There are two vertical-shaft mixers in use in the concrete mixing plant, and when the older mixer needed to be renewed, the company contacted its reliable partner Steel-Kamet. The project started quickly: the decision on the realization was made last April, and in July the project was already completed.

- During two weeks in July, the necessary demolition work was carried out, new equipment was installed, and electrification, programming and testing were carried out. In addition to the vertical-shaft mixer and skip hoists, the complex included cement screw conveyors, a water weigher, and an additive weigher. We were responsible for the entire planning, electrification, and necessary deliveries of the project, says Mikko Rautio, Steel-Kamet's Sales Director.

When the schedule matters

Especially important to the success of the project was thorough planning, so that the renewal of the mixer and skip hoists would take place on the promised schedule. When parts are changed in a plant that is in operation around the clock every day of the year, the main goal is to stop the concrete mixing plant and with it the production of the plant for the shortest possible time.

- It was a large-scale and fast-scheduled project, the planning and realization of which went excellently. I would say that the project was 101 percent successful, says Jarmo Puoliväli, Betset's Production Manager.

A rarely excellent product

A product manufactured by the Italian company Eurostar, part of the German BHS Group, was selected as the new vertical-shaft mixer. Mikko Rautio visited the factory in Italy and thought that the product was well suited to Betset's needs. It was the first mixer manufactured by Eurostar that was delivered to Finland. - The new innovations used in the product enable faster emptying compared to a standard mixer. When the concrete mass comes out of the mixer faster, the new portions can be weighed faster. In this way, the efficiency of the plant can be increased with the help of the product, Rautio explains.

The new vertical-shaft mixer will make the operation of the Nurmijärvi plant more efficient by approximately one hundred hours per year. - We are only talking about seconds for one dose, but when the doses are weighed daily around the clock, the change is ultimately very significant, Rautio calculates.

According to Rautio, the product's excellence is indicated by the fact that the first batch of concrete made with the mixer could be used directly: - No waste concrete was produced at all, which is very rare.

A smaller carbon footprint in the future

Puoliväli is very satisfied with the equipment choices made in cooperation with Steel-Kamet: - The concrete is of more uniform quality, which contributes to our success. When the production of concrete mass works well, the proportion of waste concrete also decreases, and no extra costs arise.

The new equipment installed in the project will also benefit the environment and the plant workers. - We have been able to reduce the proportion of cement, which is a hot spot in terms of emissions. The plant's carbon footprint will decrease, Puoliväli says. The new devices are also significantly quieter and more functional in terms of work ergonomics, which improves the working environment at the plant.

Comprehensive service

Steel-Kamet considers the customer's needs very far-sightedly in the realization of projects. Employees from Betset were also asked to participate in the installation of the equipment at the Nurmijärvi plant, so that they could immediately get to know how the new equipment works. - In this way, the customer can use the new equipment as efficiently as possible, Rautio says.

The close cooperation between Steel-Kamet and Betset has been going on for a long time - for more than 25 years. Betset's Espoo plant, completed last year, was also realized in cooperation with Steel-Kamet. - Cooperation has always been uncomplicated. Although times are challenging, we will continue to make reforms to our factories and even open new sites. As a partner, Steel-Kamet plays a key role in these, Puoliväli concludes.